0 Air Detector Tests - Performance and Function

- Autoclave Validation

- by Kevin Peacock

- 30-07-2024

These tests are used to set the air detector to register a fault whenever residual air is sufficient to cause a failure of the small load test and the full load test.

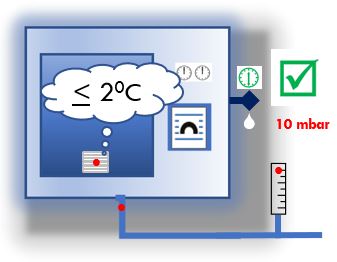

The air detector should register a fault when, at the commencement of the equilibration time, residual air causes a difference of more than 2°C between the lowest temperature measured in the standard test pack and the temperatures measured at the reference measurement point of the chamber.

In certain applications and setting (e.g. industrial settings) the performance of the air detector can be based on the defined process parameters and the product of product family(ies) that the sterilization process is designed to process.

ISO 17665:2024 - Annex C.7

Introduction

Where a sterilizer employs vacuum as a means of removing air for the load prior to sterilization an air detecting system may be installed and used to determine whether any air or non-condensable gas present in the chamber is sufficient to impair the sterilizing process. The air detecting system should cause a fault to be indicated if the amount of air or gas in the chamber at the start of the plateau period is sufficient to depress the temperature in the centre of the load more than 2°C below the temperature in the reference measurement point, (typically the drain).

Correctly set up and air detector will enhance the security of the product sterilized. It is not an alternative process to effective planned preventative maintenance or other recommended periodic tests, such as the Air Leakage Flowrate Test or Bowie and Dick Test.

Test Procedure

Advice should be sought from the sterilizer manufacturer who can advise on the correct settings for the air detector. The process of setting up the air detector can be lengthy and complex in the absence of manufacturers guidance and information. Typically, the manufacturers should be able to provide the following information: -

- The default sensitivity set point of the air detector system that will cause the sterilizer control system to indicate a fault condition.

- The set point which will trigger the air detecting system check.

- The level of vacuum leak rate that will cause this level to be exceed.

Verify that the chamber integrity is satisfactory by performing an Air Leakage Flowrate Test. Once satisfied there are three tests to be performed in sequence, the small load, full load and function test.

Prior to commencing the tests, install an air-flow metering device to the chamber, usually by means of the port provided by the manufacturer for connection of test sensors.

Performance test for the air detector, small load

This test is designed to determine the setting for the air detector so that, with a small load, it will respond to a leak rate sufficient to depress the temperature in the test pack by no more than 2°C.

Follow the set-up procedure for the Thermometric Test Small Load If the air detector is correctly set, the test should proceed rapidly down the left-hand branch and be complete in two cycles.

Select the operating cycle with the highest sterilization temperature and standard drying time.

Place a standard test pack in the chamber, with the bottom of the pack supported 100-200 mm above the centre of the chamber base.

A fresh test pack is required for each test.

At the start of the test ensure that the air detector sensitivity is set to the value recommended by the manufacturer. The detector can be disabled in accordance with the manufacturer’s instructions.

During the air removal stage, admit air into the chamber by means of the air-flow metering device at the level sufficient to depress the temperature in the centre of the load more than 2°C below the temperature in the reference measurement point, (typically the drain).

NOTE: BS EN 285:2015, clause 19.2.2.9 instructs that the can be necessary to conduct a number of tests in order to establish the level of induced air leakage required. If the induced air leakage is found to exceed 11.0 mbar/min it recommends setting the induced leak rate to 10mbar/min (+/-1.0mbar/min), (clause 19.2.2.11). I would recommend that the test person starts this sequence of tests with a leak rate of 10mbar/min (+/-1.0mbar/min). See further reading Air Detectors

From the measured temperatures, determine the temperature depression at the start of the plateau period:

Depression, Δ T = Tc -Tp where:

Tc = temperature measured in the active chamber discharge;

Tp = temperature measured in the centre of the test pack.

When the small load test is complete, proceed immediately to the air detector, fullload test.

Performance test for the air detector, full load

This test is designed to show that an air detector set to respond correctly during the small load test will also respond correctly with a full load. It is normally carried out immediately after a satisfactory completion of a small load test.

If the air detector has been correctly set, the test should proceed rapidly,

Select the operating cycle used for the air detector, small load test.

The load is a standard test pack placed in the chamber in a position identified by the manufacturer as the most difficult to sterilize, with the remaining usable chamber space filled with a full load appropriate to the type of sterilizer under test, (see Thermometric Test Full Load). Place temperature sensors as for the Thermometric Test Small Load.

A fresh load is required for each cycle

At the start of the test ensure that the air detector sensitivity and leak rate settings are identical to those established in the air detector, small load test.

If, during the test, it becomes necessary to readjust the air detector setting, repeat the small load test and verify the air detector settings.

Function test

The air detector function test is used to provide assurance that the setting of the air detector remains valid. This test is typically performed as part of the weekly schedule of tests.

Set the air-flow metering device to the setting established during the air detector, small load test.

Place a standard test pack in the chamber, with the bottom of the pack supported 100-200 mm above the centre of the chamber base.

Select and start the operating cycle.

The test should be considered satisfactory if the operating cycle is aborted and a fault is indicated. If the cycle is not aborted, then the advice of the manufacturer should be sought.

When the air detector tests are complete, the settings of the air detector sensitivity, the automatic controller trigger point, and the air-flow metering device and induced vacuum leak rate should be noted in the test report.

Product Load

Where the performance of the air detector on the user’s production load (industrial settings) cannot be predicted from the above standard test loads, it may be necessary to repeat the air detector small and full load tests on the user’s load configurations.

In the context of GMP operation the small and full load is typically the minimum and maximum load pattern for each load configuration. If the user load is a fixed load, I would recommend the full load be replaced with the users loading configuration.

Return to Schedule of Tests