0 Steam Quality Testing

- Autoclave Validation

- by Kevin Peacock

- 27-08-2024

Non-condensable gas in the steam affects air dilution in the chamber. Water in the steam affects residual moisture in the load. Superheated steam can prevent or delay the formation of moist heat on the surfaces which need to be sterilized. Wide variations in delivery pressure to the sterilizer is indicative of inadequate steam capacity and this can affect the validity of thermometric measurements for assessing the presence of saturated steam. Contaminants can cause corrosion and deposit toxic substances on the product.

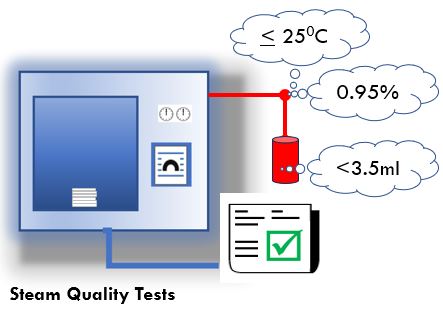

When tested by the methods given in BS EN 285 the following should apply to the quality of steam supplied to the sterilizer:

- a maximum of 3,5 ml of gas collected from 100 ml of condensed steam;

- a minimum dryness value of 0,95 (5% moisture);

- a maximum of 25 °C of superheat when expanded to atmospheric pressure;

- contaminants

- fluctuations in steam pressure not exceeding ±10% of the nominal gauge pressure measured at the inlet to the final pressure reduction valve.

ISO 17665:2024 - Annex C.10

A continuous supply of saturated steam is required for steam sterilization. Too high a level of non-condensable gases will prevent the attainment of sterilizing conditions; too little moisture carried in suspension can allow the steam to become superheated during expansion into the chamber, while excess moisture can cause damp loads.

For all physical steam quality tests, the steam should be sampled from the steam service pipe to each sterilizer. The measurements are taken during a period of maximum steam demand, when steam is first admitted to the sterilizer chamber.

Silicone rubber tubing is porous to steam and should not be used to carry steam in these tests.

Steam pipework and sampling apparatus will be hot, and adequate precautions should be taken against getting burnt. Thermal gloves and safety glasses should be worn.

Non-condensable gas test

This test is used to demonstrate that the level of non-condensable gases in the steam will not prevent the attainment of sterilization conditions in any part of the load. Possible sources of non-condensable gases are discussed in paragraph 3.29, ‘Non-condensable gases’. The method described should not be regarded as measuring the exact level of non-condensable gas, but as a method by which the provision of acceptable steam quality can be demonstrated.

Steam superheat test

This test is used to demonstrate that the amount of moisture in suspension with steam from the service supply is sufficient to prevent the steam from becoming superheated during expansion into the chamber. The test assumes that the steam supply pressure is nominally 4.0 bar gauge. If the supply pressure differs from this it might be necessary to amend the acceptance criteria accordingly.

Steam dryness test

The accurate measurement of the percentage of moisture content in the steam is difficult, and the traditional methods, where constant steam flow is required, are not suitable for sterilizers. This test should be regarded not as measuring the true content of moisture in the steam, but as a method by which the provision of acceptable steam quality can be demonstrated. Possible sources of excessive moisture are discussed in paragraph 3.18, ‘Dryness’.

The test is carried out immediately after the superheat test.

Return to Schedule of Tests